The Acorn Area™ is a revolutionary instrument designed to measure the surface area of nanoparticles dispersed in a liquid. This patented nuclear magnetic resonance (NMR) based method offers many advantages in comparison with conventional surface area techniques. Measurements take about 5 minutes from start to finish. No sample preparation— such as drying or degassing— is required. High concentration dispersions are measured directly, without dilution. Acorn Area measurements are orders of magnitude faster than any other surface area measuring technique.

The Acorn Area™ is a revolutionary instrument designed to measure the surface area of nanoparticles dispersed in a liquid. This patented nuclear magnetic resonance (NMR) based method offers many advantages in comparison with conventional surface area techniques. Measurements take about 5 minutes from start to finish. No sample preparation— such as drying or degassing— is required. High concentration dispersions are measured directly, without dilution. Acorn Area measurements are orders of magnitude faster than any other surface area measuring technique.

The surface area of particles influences many aspects of product performance such as the hiding power of pigments, the activity of catalysts, the taste of food, the potency of drugs and the bioavailability of drugs. In the past, surface area measurements were made using methods such as gas adsorption, mercury porosimetry, and gravimetric analysis. These methods all have the same limitation; they are only useful for analyzing dry powders.

However, the overwhelming majority of manufactured products involve dispersions of particles in a liquid, either in the final state or at some stage of production. While dry powder methods are suitable to test incoming dry powder raw materials, they cannot provide information about the particles when dispersed in a liquid. To date this has not been possible other than to estimate the surface area from particle size measurements or to perform time- consuming adsorption isotherm or titration measurements.

Liquid in contact with the particle surface behaves differently from that of the bulk, or “free” liquid in response to a changing magnetic field. The NMR relaxation time of liquid on the particle surface is much shorter than that of the bulk liquid.

This difference can be several orders of magnitude. The relaxation time of particles dispersed in a liquid is an average of the two relaxation times, weighted by the relative amount of liquid on the particle surface and that in the free liquid. This is a direct measure of the particle surface area.

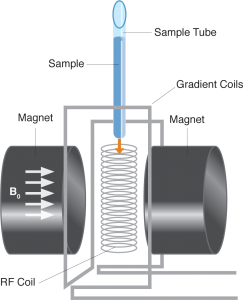

To make a measurement, place a 0.5ml sample in a sample tube and insert it into the Acorn AreaTM. The sample resides within a coil located between two permanent magnets. A static, uniform magnetic field, B0, causes the protons within the liquid to align with B0; this process typically takes a few seconds.

At the start of the measurement, a short radio frequency (RF) pulse excites the coil at a frequency of approximately 14 MHz. This pulse produces a large magnetic field, inducing a temporary shift in the magnetic orientation of the sample protons. When this induced field ceases, the protons of the sample fluid then realign with the static field, B0. This realignment induces a decaying voltage in the coil, called the “free induction decay” (FID).By using specific pulse sequences,(combinations of RF pulses of varying length and time between pulses)the sample T1 (longitudinal) and T2 (transverse) relaxation times are measured.Although T1 and T2 are different, their shift between liquid in the bulk and liquid on the surface is similar, and both can be used to determine the surface area.

AreaQuant™, the Acorn Area software,measures T1 using an inversion recovery pulse sequence, and measures T2 using the CPMG pulse sequencing method. The resulting data are analyzed to determine the relative proportion of bound and free liquid and the corresponding particle surface area. There are no assumptions about the sample particle size (distribution) or shape used to determine surface area; the wetted area is measured directly. The user inputs the particle dispersion weight concentration, the liquid and particle density. The particle-to-liquid volume ratio (used in the calculation of surface area) is automatically determined.

The resulting data are analyzed to determine the relative proportion of bound and free liquid and the corresponding particle surface area. There are no assumptions about the sample particle size (distribution) or shape used to determine surface area; the wetted area is measured directly. The user inputs the particle dispersion weight concentration, the liquid and particle density. The particle-to-liquid volume ratio (used in the calculation of surface area) is automatically determined.

There are two Operational Modes in the software setup: Standard (or QC) Mode and Advanced (or R&D) Mode. The former is the mode used to measure surface area. In R&D mode, the instrument behaves like a traditional NMR spectrometer capable of a wide range of low-resolution NMR measurements.

Measurements with the Acorn Area are simple and easy. Dispersions can be measured non-invasively, without dilution. The upper limit in concentration is essentially unlimited; the lower limit is about 1-2%. Using this automatic mode, AreaQuant™ then determines all the measuring parameters needed such as  the amplitude and duration of the pulses, the number of repetitions, etc. without operator intervention. This ensures measurements are made with the highest resolution and repeatability without a great deal of operator training. To simplify method development, the software also features an automatic test parameter file configuration based on an estimated T1 or T2 time input by the user. Once a set of parameters are defined, operation of the Acorn Area is simple: just enter the operator name and sample information – the software does the rest!

the amplitude and duration of the pulses, the number of repetitions, etc. without operator intervention. This ensures measurements are made with the highest resolution and repeatability without a great deal of operator training. To simplify method development, the software also features an automatic test parameter file configuration based on an estimated T1 or T2 time input by the user. Once a set of parameters are defined, operation of the Acorn Area is simple: just enter the operator name and sample information – the software does the rest!

AreaQuant™ operates on virtually all Windows Platforms, including XP®, Vista®, and Windows® 7. Data files are saved in XML format, easily opened with Microsoft Excel or Open Office. Reports are saved in RTF format. Graphs may be copied to the clipboard or saved in JPG or PNG formats. To make sure you are using the most up to date software available, updates may be downloaded and installed via the internet with a single click of the mouse.

Acorn Drop

The Acorn Drop uses patented nuclear magnetic resonance (NMR) technology to measure emulsion or foam droplet size and distribution, entirely without dilution. Simply place 0.5 ml of sample in a 5mm tube, insert it into the Drop and press START. The results are available a few minutes later. In contrast, conventional particle sizing techniques such as laser diffraction require extensive dilution of the emulsion in order to measure droplet size.

The Acorn Drop uses patented nuclear magnetic resonance (NMR) technology to measure emulsion or foam droplet size and distribution, entirely without dilution. Simply place 0.5 ml of sample in a 5mm tube, insert it into the Drop and press START. The results are available a few minutes later. In contrast, conventional particle sizing techniques such as laser diffraction require extensive dilution of the emulsion in order to measure droplet size.

The measuring range of the Acorn Drop is extremely broad – from 10nm to 100 microns. High concentration, highly viscous, opaque and light-sensitive emulsions can be measured directly as well as nano or or micro emulsions (that cannot be diluted due to their composition dependence). Our approach is nondestructive – the same sample emulsion can be studied minutes, days or weeks later, facilitating analysis of emulsion stability.

The XiGo Acorn Drop is a nuclear magnetic resonance spectrometer (NMR) configured to provide 1-dimensional imaging and diffusion. The spin-echo of the emulsion or foam is measured as a function of the space between magnetic field gradient pulses. The attenuation of the echo as a function of gradient spacing determines the diffusion coefficient and the corresponding droplet size.

Acorn Flow

An external stirrer may be used to keep particles in suspension while they reside inside the beaker waiting to be measured. The Acorn Flow enables the user to measure the influence of additives such as surfactants and dispersants on the particle-liquid interface of nanoparticle dispersions. Surfactants are among the most expensive components in a nanoparticulate dispersion, and optimization of their concentration is important in maximizing formulation profitability. The presence of surface active agents on the nanoparticle surface markedly alters the relaxation time of the dispersion until complete coverage of the particle surface area is achieved. Thereafter, additional surfactant does not change the relaxation time significantly. The Acorn Flow is also invaluable in monitoring other changes at the particle liquid interface, such as flocculation. The Acorn Flow is an ideal tool for use in formulation development in virtually any industry, yet is simple enough for routine use in a quality laboratory.

The Acorn Flow temperature controller is shown below. It features a Peltier controlled environment which regulates the sample temperature via the front panel. The sample temperature is set from the front panel membrane keypad.

Measurements with the Acorn Flow are simple and easy. Suspensions and emulsions can be measured non-invasively, without dilution. Pour the sample dispersion into the Acorn Flow Temperature Controller beaker and circulate the sample into the Acorn Flow using the peristaltic pump. The test sequence is initiated with a single key stroke and within minutes, the proprietary AreaQuant software algorithm reports the measured surface area.

Maximum Fluid Pressure: 4 bars

Interface: PC via USB

Voltage: 100-240 VAC 50/60 Hz

Power Consumption: 120 Watts

LxWxH: 270x360x140 mm

Wt.: 7 kg

Temperature range: 10-75 Celsius

Voltage: 100-240 VAC, 50/60 Hz, 1.5A

Setting Resolution: 0.1Celsius

Power Consumption: 60 Watts

LxWxH: 240x260x165 mmWt: 3.5 kg