| ProbeWorkstation |

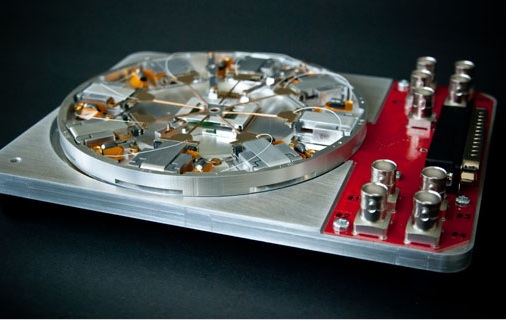

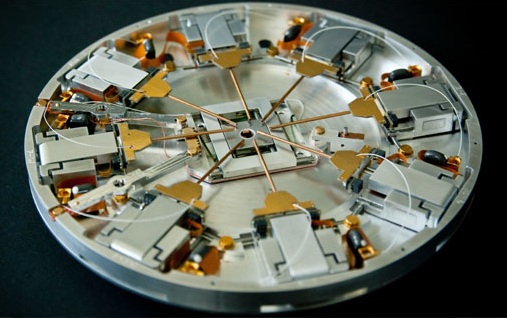

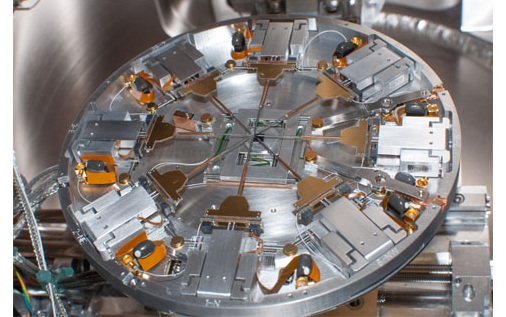

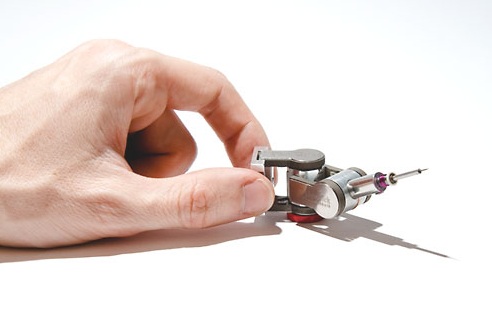

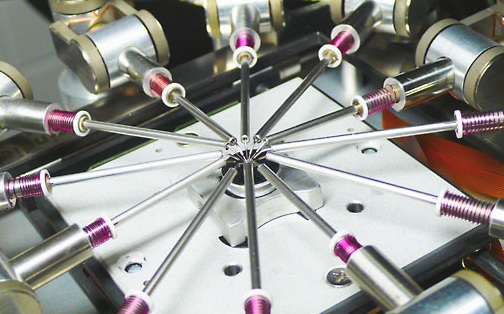

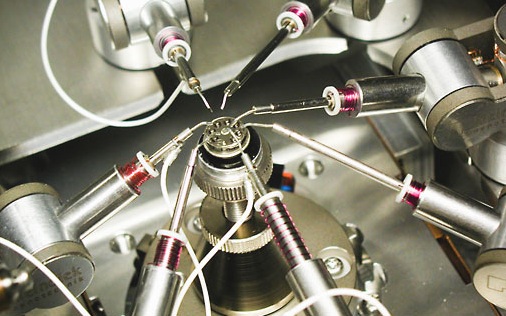

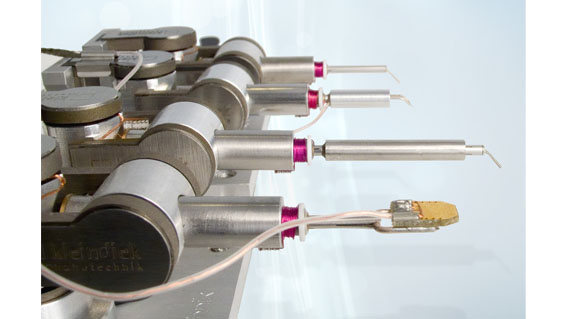

Prober Shuttle (PS8)

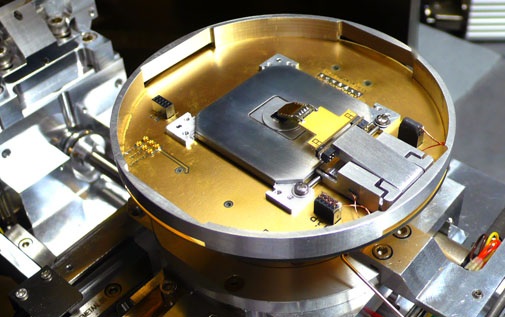

The Prober Shuttle is our latest tool for high-precision in-situ electrical nanoprobing on the 14 nm technology node – and beyond! In order to realise our vision for this product, we developed an ultra-flat three-axis manipulator with unmatched stability and precision – the MM4. The Prober Shuttle can be comprised of up to eight MM4s with the option of an ultra-flat two-axis or three-axis substage.

The entire height of the system is 10 mm, making it compatible with a wide range of SEM load-locks and thus helping you to achieve a higher sample throughput. The Prober Shuttle also offers low-current, low-capacity measurement capability and is fully compatible to the Advanced Probing Tools hardware and software suite including the Live Contact Tester and Electron Beam Induced Current imaging modules.

Compact & flexible

- Small and practical

- Plug-and-play system with modular components

- Interfacing solutions for most SEM/FIB instruments (including load-lock compatibility)

- Fast setup and removal

- Pioneering cabling technology

Clear & simple

- Intuitive control interfaces and software

- User-friendly and easy to learn

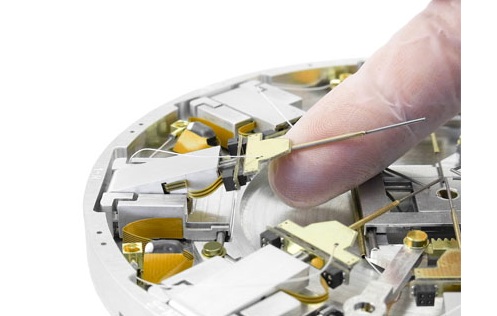

- Quick and easy probe tip exchange

- Compact, stand-alone electronics

- Effortless work with multiple manipulators

Robust & stable

- Excellent stability

- Low drift (1 nm/min)

- Reliable operation (one year endurance test)

- Virtually insusceptible to vibrations

- Fast pre-positioning by hand

Fast & precise

- High operating velocity (up to 10 mm/sec)

- Sub-nanometer resolution (0.25 nm)

- No backlash or reversal play

- Extensive working range

- Coarse and fine displacement in one drive

Overview

- Total height: 10 mm

- Total width: 140 mm

- Maximum sample size: 20 mm — 20 mm — 1 mm

- Weight: 200 g + SEM/FIB dovetail

Next generation micromanipulators

A = left / right B = up / down C = in / out

- Operating range: A = 7 mm, B = 90°, C = 5 mm

- Resolution: A = < 0.5 nm, B = 9 nm, C = < 0.5 nm

- Low drift: 1 nm/min

Low-capacity, low-current measurements

- Noise: 25 fA @ 1 Hz

- Insulation leakage current: <50 fA/V

- Signal conductor resistance: <5 Ω

- Maximum voltage: 100 V

- Maximum current: 100 mA

The current challenge in the field of microscopy is to add the ‘hand’ function to the electron microscope to allow physical manipulation and characterization at the micro- and nanoscale. The NanoWorkstation is a powerful, dedicated system that performs such tasks with ease and can be integrated into most commercially available SEMs and FIBs.

The NanoWorkstation makes high-end manipulation practical and affordable for industrial and research labs, allowing you to remain competitive in a world where critical dimensions are now in the nanometer range.

The module-based system offers high versatility, giving you the flexibility to perform numerous different specialized applications by simply changing the tool attached to the front of the manipulator, whether it is moving, assembling, preparing, rotating, pushing, probing, feeling, listening, gripping or any other task you can imagine.

Compact & flexible

- Small and practical

- Plug-and-play system with modular components

- Interfacing solutions for most SEM/FIB instruments (including load-lock compatibility)

- Fast setup and removal

- Pioneering cabling technology

Clear & simple

- Intuitive control interfaces and software

- User-friendly and easy to learn

- Quick and easy probe tip exchange

- Compact, stand-alone electronics

- Effortless work with multiple manipulators

Robust & stable

- Excellent stability

- Low drift (1 nm/min)

- Reliable operation (one year endurance test)

- Virtually insusceptible to vibrations

- Fast pre-positioning by hand

Fast & precise

- High operating velocity (up to 10 mm/sec)

- Sub-nanometer resolution (0.25 nm)

- No backlash or reversal play

- Extensive working range

- Coarse and fine displacement in one drive

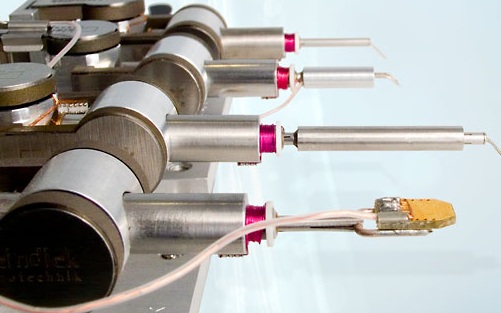

Four MM3A-EM Micromanipulators

The NanoWorkstation is based on four of our versatile MM3A-EM micromanipulators. These can be fitted with a range of plug-ins as well as customised tools. The micromanipulators can be mounted to almost any SEM or FIB/SEM on the market.

Specifications

- The industry standard three-axis manipulator with unmatched stability and precision

- Dimensions: 62.1 mm — 20.4 mm — 25.4 mm

- Operating range: A and B = 240°, C = 12 mm

- Speed: A and B up to 10 mm/s, C up to 2 mm/s

- Resolution: A = 10-7 rad (5 nm), B = 10-7 rad (3.5 nm), C = < 0.5 nm

A = left / right B = up / down C = in / out

Two MGS2-EM Microgrippers

The NanoWorkstation includes two microgrippers for handling nanowires, CNTs, or other small objects.

Specifications

- High-resolution gripper for transport and assembly of micro-sized objects

- Gripping area: (5 to 10 μm)2

- Resolution: 20 nm

- Gripping force: 5 to 5000 μN (variable)

- Maximum span range: 20 to 40 μm

Two Rotation Tips

The NanoWorkstation also contains two RoTip-EM rotational tips that add a fourth degree of freedom to the MM3A-EM. The ‘wrist rotation’ module can be combined with the microgripper or force sensing plug-ins for added flexibility.

Specifications

- Fourth degree of freedom for the MM3A-EM

- Travel: 360° unlimited

- Speed: up to 6 rad/s

- Resolution: 0.1°

- Torque: 0.01 mNm

Force Measurement System

The NanoWorkstation is complemented by the FMS-EM sensing system. The Force Measurement Tips (FMTs) can be used to perform tensile or compression tests on small samples.

Specifications

- Force and resonance feedback using piezo-resistive sensor technology

- Tip radius: < 20 nm

FMT-400 sensor

- Tip force constant (calculation): 2 to 4 N/m

- Maximum tip force: 80 μN¹

- Resistance: 500 to 650 Ω

- Sensitivity: 3.1 x 10-3 mV/nm at Vbridge = 2.5 V²

FMT-120 sensor

- Tip force constant (calculation): 30 to 40 N/m

- Maximum tip force: 360 μN¹

- Resistance: 500 to 650 Ω

- Sensitivity: 18.8 x 10-3 mV/nm at Vbridge = 2.5 V²

¹ Calculated with assumptive deflection of 10% and the lowest force constant.

² Dependent on the bias voltage (Vbridge) that is applied to the series resistance of sensor and reference.

iProbe Control Interface

The NanoWorkstation includes iProbe – a mouse control interface for the micromanipulators. iProbe provides intuitive and seamless control of the micromanipulators’ motion using the same mouse used to drive the microscope.

Specifications

- Dynamic 3D control for four probers

- Intuitive, user-friendly and easy to learn

- Precision through six orders of magnitude

- Runs on microscope PC or laptop

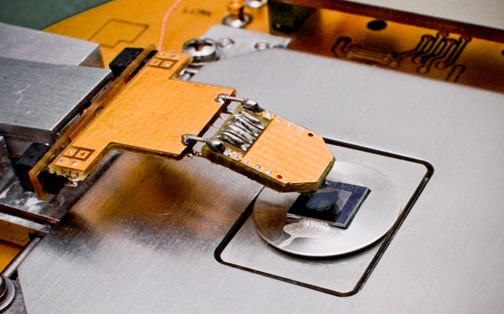

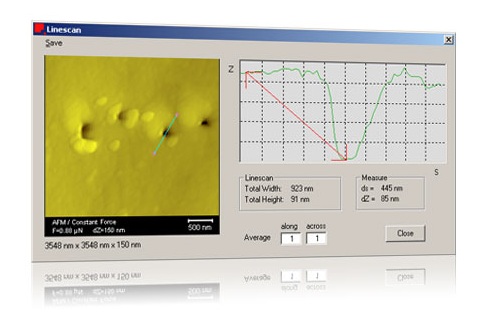

The SuperFlat AFM combines the power of SEM and AFM. Information on lateral dimensions and material from in-situ inspection can be complemented by precise AFM topographical and frictional information. The effortless availability of these two sets of data is unique to such a system and opens new avenues of investigation and characterisation.

The most amazing feature of the SuperFlat AFM is its size. The tool is flat and compact enough to fit through the majority of SEM load-locks, allowing ease of use and increasing throughput. In addition, its size offers enormous stability and vibration dampening advantages, which are particularly attractive when using the tool ex-situ.

Design efforts also included ensuring easy handling and tip exchange. A sample or tip exchange takes only a minute and a tedious laser adjustment process is not required.

- 3D information from simultaneous SEM and AFM pictures

- Notably compact (height 10 mm)

- Simple to operate

- Load-lock compatible

- Extremely stable operation

- Easy sample and tip exchange without laser adjustment

- Can be used in combination with micromanipulators and other in-situ and ex-situ tools

- Works in air and in SEM

- Intuitive control interfaces and software

- Reliable operation (one year endurance test)

- Virtually insusceptible to vibrations

Overview

- Total system height: 10 mm

- Total system width: 100 mm

- Weight: 100 g + SEM/FIB dovetail

Coarse positioner

A = left / right B = up / down C = in / out

- The ultra-flat three-axis manipulator with unmatched stability and precision

- Operating range: A = 10 mm, B = 90°, C = 5 mm

- Resolution: A = < 0.5 nm, B = 5 nm, C = < 0.5 nm

Scanning unit

- Scan range: X and Y = 14 μm, Z = 4 μm

- Resolution: 0.5 nm

- Load: 30 g

- Lift: 15 g

- Maximum sample size: 15 mm — 15 mm — 1 mm

Sensor

- Operates in contact mode and dynamic mode

- Length: 400 µm

- Width: 50 µm

- Height: 4 to 5 µm

- Tip radius: < 20 nm

- Tip height: > 5 µm

- Tip force constant (calculation): 2 to 4 N/m

- Maximum tip force: 80 μN¹

- Resistance: 500 to 650 Ω

- Sensitivity: 3.1 x 10-3 mV/nm at Vbridge = 2.5 V²

Controllers and softwrare

Our customers can choose between two controllers. Please refer to the next two tabs above.

¹ Calculated with assumptive deflection of 10% and the lowest force constant.

² Dependent on the bias voltage (Vbridge) that is applied to the series resistance of sensor and reference.

Nanosurf

Soon also available with the new C3000 controller… Please see the brochure linked in the right side column.

- Data acquisition: 16-bit data acquisition with up to 16 lines/s

- Data points: Up to 2048 x 2048 scan area data points

- Spectroscopy: Up to 65536 spectroscopy data points

- Tilt compensation: Hardware tilt compensation

- Scanner drive: 16-bit

- Data transfer: USB 2.0 connection to computer

Nanonis (Specs)

- Data acquisition: 16-bit data acquisition with up to 100 lines/s

- Data points: Up to 8192 x 8192 (also non-square pixels)

- Spectroscopy: 32 – 1M datapoints (per curve)

- Scanner drive: 22-bit, patented hrDAC

- Data transfer: LAN (TCP/IP)

SuperFlat AFM uygulaması ile ilgili daha fazla bilgi için tıklayınız.

| Micromanipulator |

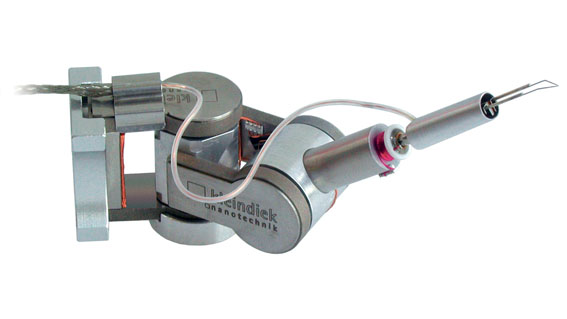

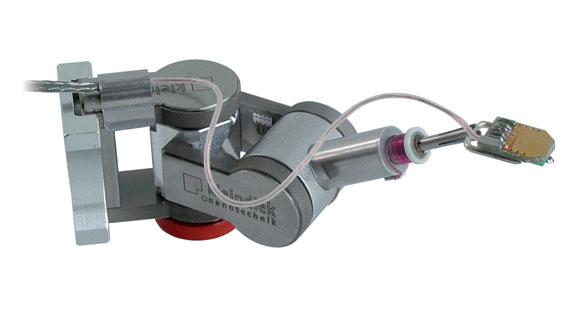

Micromanipulator for Electron Microscopy

Over the last few years, the MM3A-EM micromanipulator has created an unparalleled new dimension of quality in the field of Electron Microscopy. It is employed in a wide spectrum of SEM, FIB and other microscopes for an even wider range of applications and it has become the industry standard for OEM and retrofit solutions with well over 2000 units in the field.

Give your microscope a hand: use the MM3A-EM to add new capabilities and functionality to your instrument.

Compact and flexible

- Small and practical

- Plug-and-play system with modular components

- Interfacing solutions for most microscopes

- Fast setup and removal

- Effortless work with multiple manipulators

- Useful plug-in tools

Clear and simple

- Result-oriented operation and increased throughput

- Intuitive control interfaces and software

- User-friendly and easy to learn

- Quick and easy tool exchange

- Compact, stand-alone electronics with PC interface

- Pioneering cabling technology

Robust and stable

- Compact construction delivers higher resonance frequencies

- Excellent stability

- Low drift (1 nm/min)

- Reliable operation (one year endurance test)

- Virtually insusceptible to vibrations

- Fast pre-positioning by hand

Fast and precise

- No backlash or reversal play

- Sub-nanometer resolution (0.25 nm)

- Extensive working range (100 cm³)

- No “blind axis” like with cartesian systems

- Integrated coarse and fine displacement in one drive

- High operating velocity (up to 10 mm/sec)

- Length: 62.1 mm

- Width: 20.4 mm

- Height: 25.4 mm

- Weight: 45 g

- Operating range A & B: 240°

Operating range C: 12 mm - Speed A & B: up to 10 mm/s

Speed C: up to 2 mm/s - Resolution A: 10-7 rad (5 nm)

Resolution B: 10-7 rad (3.5 nm)

Resolution C: < 0.5 nm - Holding force: 1 N

- Holding torque: 3 to 4 Nmm

- Lift Y: 5 g

- Probing current range: 10 nA to 100 mA

- Maximum probing voltage: 100 V

- Probing signal resistance: 7.0 Ω

- Temperature range: 273 K to 353 K

UHV version: 273 K to 393 K

Low temp. version: 77 K to 393 K - Lowest pressure: 10-7 mbar

UHV version: 2 x 10-10 mbar - Mounting: M4 tapped hole

- Material: Stainless steel, aluminium

A = left / right B = up / down C = in / out

SuperFlat insitu AFM – imaging a calibration sample

SuperFlat insitu AFM – imaging ZrO spheres

SuperFlat insitu AFM – imaging a solar cell

SuperFlat Atomic Force Microscope – combining AFM with SEM

MM3A-EM – Micromanipulator for SEM/FIB

Parking Position for roof-mounted MM3A-EMs

Daha fazla bilgi için lütfen tıklayınız.